When selecting the right Thermal Printing Paper for your specific needs, it can be a daunting task given the variety of options available. Industry expert Dr. Emily Carter, a renowned specialist in thermal printing technologies, emphasizes the importance of choosing the right paper: "The quality of thermal printing paper directly impacts the longevity and clarity of your printed materials." This statement captures the essence of why the selection process is critical for both personal and professional applications.

Thermal Printing Paper plays a crucial role in determining the efficiency of your printing tasks. From labels and receipts to barcodes and tickets, the right paper can enhance the performance of your thermal printer while ensuring that your printed items are both durable and legible. Understanding the various types of thermal paper, their chemical compositions, and the coating techniques used can vastly improve your printing outcomes.

In this guide, we will delve into essential factors to consider when choosing Thermal Printing Paper, helping you make informed decisions that suit your printer needs. By exploring different grades, sizes, and thermal sensitivity options, you'll be better equipped to select paper that not only meets your current requirements but also supports your future printing projects effectively.

When selecting the best thermal printing paper for your printer needs, it's essential to understand the various types available on the market. Thermal printing paper primarily falls into two categories: direct thermal and thermal transfer paper. Direct thermal paper is coated with a heat-sensitive layer that turns black when exposed to heat from the printer's thermal elements. This type is ideal for short-term use, such as labels and receipts, as it can fade over time when exposed to light or heat.

On the other hand, thermal transfer paper involves a ribbon that transfers ink onto the paper as heat is applied. This method produces more durable and long-lasting prints, making it suitable for labels that require longevity or exposure to various environmental conditions, such as moisture or abrasion. Understanding these differences helps in choosing the right thermal printing paper based on your project's specific requirements, including durability, print quality, and intended use.

When selecting thermal printing paper, several key factors must be considered to ensure optimal performance and quality. First and foremost, the paper's coating and smoothness play a crucial role in the printing process. According to a study by the International Association of Printing Technologies, higher-quality thermal papers often feature a specialized coating that improves ink absorption and enhances print clarity. This is particularly important for businesses that require crisp receipts or labels, as any compromise in quality can affect readability and overall professionalism.

Another critical aspect to keep in mind is the paper's size and compatibility with your printer. Not all thermal printers support the same paper dimensions or types. A report from the National Printing Association indicates that understanding the specifications of your printer and matching them with the correct paper dimensions is vital to avoid paper jams and ensure seamless operation.

Tips: Always check the manufacturer’s guidelines for paper thickness and width to find the best match for your thermal printer. Additionally, consider the environmental impact; opting for BPA-free thermal paper not only protects the health of your employees but also aligns with sustainable business practices.

Moreover, the environmental conditions where the prints will be used should be examined. For instance, thermal papers designed to withstand high humidity or temperature variations are essential for outdoor applications. Research has shown that using the appropriate thermal paper can significantly extend the life of printed materials—up to 20% longer in hostile conditions—ensuring both durability and reliability in various settings.

When selecting thermal printing paper, compatibility with your specific printer model is crucial. Different printers may have varying requirements in terms of paper thickness, sensitivity, and size. It's essential to check the specifications provided by your printer’s manufacturer, as this information will guide you toward the type of thermal paper that will perform optimally. Some printers may only work well with certain grades of thermal paper, which can affect print quality and longevity.

Another aspect to consider is the type of thermal printing technology used by your printer. Direct thermal printers utilize heat-sensitive paper that turns black when exposed to heat, while thermal transfer printers require ribbons in addition to the paper itself. Ensure that the thermal paper you are considering aligns with your printer type to avoid performance issues. Additionally, reading user reviews and seeking recommendations from other users with similar printing needs can provide insights into the best thermal paper options for your specific model.

| Paper Type | Printer Compatibility | Barcode Quality | Thickness (mm) | Size (mm) | Typical Use |

|---|---|---|---|---|---|

| Thermal Paper | Direct thermal printers | High | 0.08 | 80 x 70 | Receipts, labels |

| Synthetic Paper | Thermal transfer printers | Medium | 0.10 | 100 x 150 | Durable labels |

| Thermal Transfer Paper | Thermal transfer printers | High | 0.05 | 60 x 100 | Shipping labels |

| Self-Adhesive Thermal Paper | Direct thermal printers | Medium | 0.08 | 75 x 100 | Product labels |

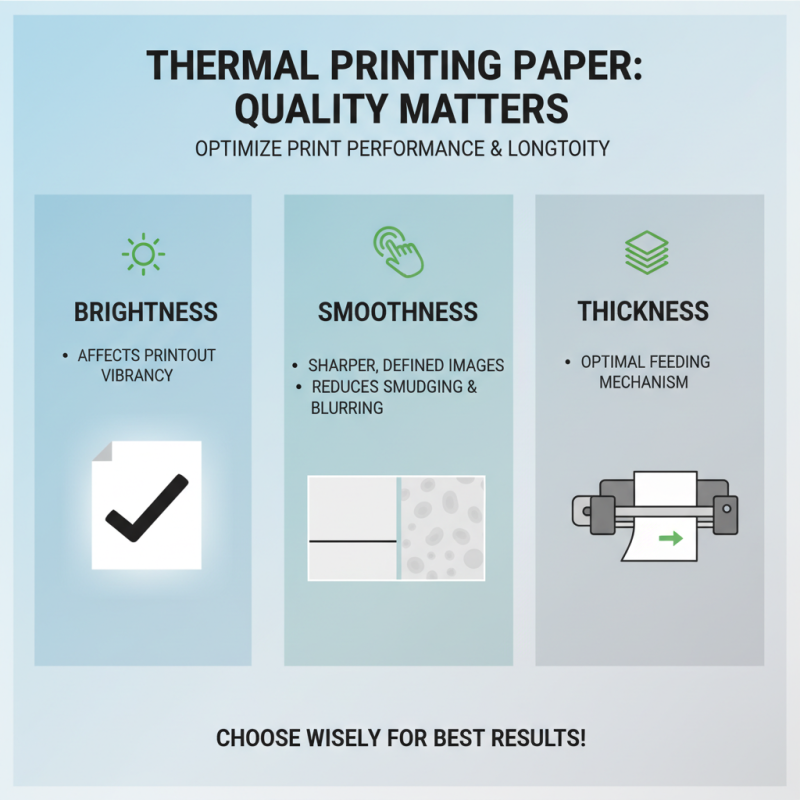

When selecting thermal printing paper, assessing the quality of the paper is paramount for achieving optimal print performance. High-quality thermal paper guarantees not only compatibility with your printer but also enhances the longevity and clarity of the printed images. Key characteristics to consider include the paper's brightness, smoothness, and thickness. Brightness affects the vibrancy of the printouts, while a smoother surface allows for sharper and more defined images, reducing the risk of smudging and blurring. Additionally, the thickness of the paper can influence the printer’s feeding mechanism, making it essential to choose a paper that works seamlessly with your specific model.

Another critical aspect of paper quality is its coating, which plays a crucial role in determining how well the image adheres to the surface. The coating can vary among different papers, affecting how well they react to heat and pressure during the printing process. Papers with superior coatings generally yield high-quality prints that resist fading over time, ensuring that important information remains legible. Lastly, consider environmental factors such as resistance to moisture and temperature fluctuations, as these can impact the durability and performance of the printed material. By carefully evaluating these characteristics, you can choose the best thermal printing paper that meets your specific printing needs and ensures the best possible outcomes.

When selecting thermal printing paper, it is essential to consider not only the performance and quality of the paper but also its environmental impact. Sustainability in thermal paper production can be influenced by the raw materials used, the manufacturing processes, and the life cycle of the paper itself. Opting for papers that are made from recycled materials or sourced from responsibly managed forests can significantly lower the ecological footprint associated with thermal printing. Additionally, selecting products that are free from harmful chemicals and are easily recyclable can further promote a more sustainable approach to printing needs.

Moreover, the disposal methods of thermal paper should also be taken into account. Many thermal papers contain BPA or BPS, which can pose potential environmental hazards when disposed of improperly. Choosing BPA-free thermal paper is not only beneficial for health concerns but also supports a sustainable waste management practice. Consumers and businesses alike can contribute to reducing pollution by ensuring that their thermal paper usage aligns with eco-friendly practices, encouraging manufacturers to adopt more humane and sustainable production methodologies. Making informed decisions about thermal printing paper is crucial for fostering a sustainable environment.