In the rapidly evolving landscape of printing technology, selecting the right Thermal Printing Paper is crucial for businesses aiming to enhance operational efficiency and reduce costs. According to a recent industry report published by Smithers Pira, the global thermal printing market is projected to reach $31 billion by 2025, driven by heightened demand across various sectors such as retail, healthcare, and logistics. As companies increasingly adopt thermal printing solutions for labels, receipts, and tickets, understanding the specific requirements of thermal printing paper becomes paramount.

The choice of Thermal Printing Paper can significantly impact print quality, durability, and environmental sustainability. Research from the International Journal of Advanced Manufacturing Technology indicates that improper paper selection can lead to a 15% increase in operational costs due to waste and reprinting. Furthermore, 70% of businesses report that using high-quality thermal printing paper has improved their customer satisfaction ratings, underlying the importance of making informed decisions. With a wide range of options available in the market, from standard to specialty papers, organizations must assess their specific application needs and the compatibility of paper with their printing devices to achieve optimal performance.

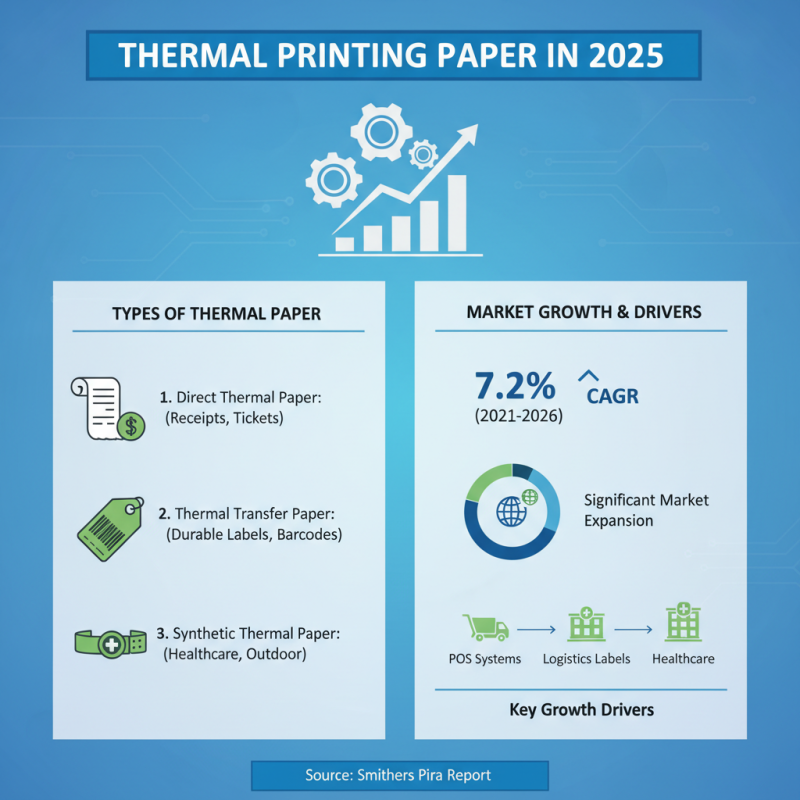

In 2025, understanding the various types of thermal printing paper is crucial for businesses looking to optimize their printing processes. The market for thermal paper is expected to grow significantly, with a projected CAGR of approximately 7.2% from 2021 to 2026, as detailed in a report by Smithers Pira. This growth is primarily driven by the increasing demand for point-of-sale systems and label printing applications across various industries, including retail, logistics, and healthcare.

There are primarily two categories of thermal printing paper: direct thermal and thermal transfer. Direct thermal paper is coated with a heat-sensitive material that turns black when exposed to heat, making it ideal for short-term use, such as receipts and shipping labels. In contrast, thermal transfer paper uses a thermal ribbon to transfer ink onto the substrate, providing higher durability and resistance to environmental factors. According to the latest industry research, about 60% of businesses prefer thermal transfer for applications requiring extended durability, such as product labeling and warehousing.

Choosing the right thermal paper type involves considering factors such as the intended application, storage conditions, and print longevity. As per a recent survey conducted by Technavio, organizations that select suitable thermal paper can achieve a 25% reduction in printing-related costs by minimizing waste and improving efficiency in high-volume printing environments. Understanding these nuances will equip businesses to make informed decisions tailored to their specific requirements in an increasingly competitive marketplace.

When selecting thermal printing paper in 2025, several key factors should guide your decision-making process. First and foremost, consider the paper's coat quality and sensitivity, as these significantly affect print clarity and longevity. According to recent industry reports, high-quality thermal paper typically contains a special coating that ensures sharper images and text, resulting in a print profile that meets most commercial standards. It has been noted that using superior thermal printing paper can enhance image resolution by up to 30%, which is particularly important for businesses requiring high-detail output.

Another critical factor is the environmental impact of the printing paper. The industry is witnessing a shift towards eco-friendly options, driven by consumer demand for sustainable products. Reports indicate that nearly 60% of companies are now prioritizing biodegradable and recyclable materials in their operations. Choosing thermal printing paper made from sustainable sources not only meets growing regulatory requirements but also improves brand reputation and customer loyalty. Understanding how different papers respond to various climate conditions can also impact your long-term costs, as improper storage and use can lead to significant quality degradation of prints.

Lastly, pay attention to the dimensions and compatibility of the thermal paper with your existing printing equipment. Industry data shows that mismatching paper sizes can lead to inefficiencies, causing a 15% increase in waste and operational costs. Ensuring that your paper aligns with the specifications of your printer is crucial. By evaluating these factors carefully, you can optimize your printing operations and make an informed choice that aligns with your business needs in 2025.

| Factor | Description | Considerations | Recommended Type |

|---|---|---|---|

| Paper Type | The kind of thermal paper, such as direct thermal or thermal transfer. | Consider how the paper will be used and the desired print quality. | Direct Thermal |

| Paper Thickness | The caliper of the paper, which affects durability and compatibility. | Check printer specifications for optimal thickness. | 75-80 GSM |

| Coating | The surface treatment that affects print quality and stability. | Determine if resistance to smudging or scratching is necessary. | Topcoat Paper |

| Compatibility | Ensures the paper works well with specific printers. | Verify printer model and type of printing method. | OEM Compatible |

| Environmental Impact | The sustainability of the paper production process. | Choose recyclable or eco-friendly options if important. | Recyclable Paper |

When selecting thermal printing paper, understanding the significance of paper coating and composition is essential for ensuring optimal printing results in various applications. Thermal printing paper typically consists of a base substrate coated with a heat-sensitive layer that reacts to the thermal print head.

Industry reports suggest that the composition of this coating can significantly affect the image quality, durability, and longevity of prints. For instance, according to a market report by Smithers Pira, papers with higher levels of polymer coatings can provide enhanced image clarity and resistance to smudging and fading, making them ideal for demanding environments.

Moreover, the choice of paper composition directly influences the environmental impact and cost-effectiveness of thermal solutions. A study conducted by the International Paper Association highlighted that papers with eco-friendly coatings not only meet sustainability standards but can also reduce waste and improve recycling efficiencies.

Furthermore, as consumers and businesses increasingly demand sustainable practices, opting for papers with biodegradable or recyclable coatings can align with environmental goals while maintaining functionality. This dual focus on performance and sustainability is becoming increasingly vital as we approach 2025, where market trends show a growing preference for environmentally responsible printing solutions.

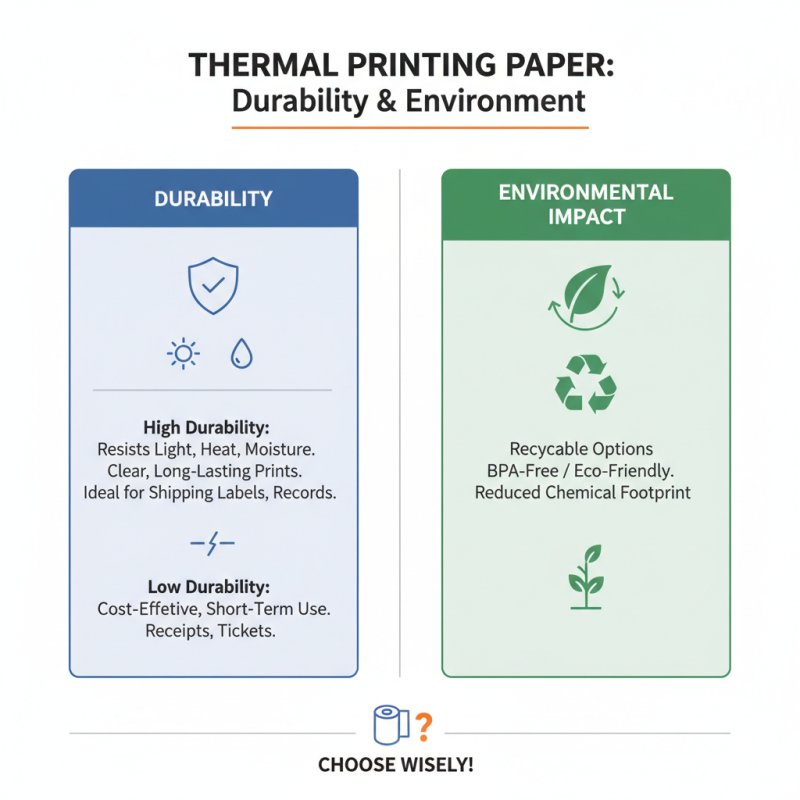

When selecting the right thermal printing paper for your needs, durability and environmental impact are critical factors to consider. Durability refers to how well the paper withstands various conditions, such as exposure to light, heat, and moisture. Higher durability papers often result in clearer and longer-lasting prints, making them suitable for applications that require resilience, like shipping labels or long-term records. In contrast, less durable options may be appropriate for short-term use, where cost savings take precedence over longevity.

On the environmental front, the choice of thermal printing paper can significantly impact sustainability efforts. Some papers are manufactured using eco-friendly processes and materials, minimizing chemical use and reducing waste. Additionally, considering whether the paper is recyclable or made from recycled content can also guide your selection. As consumers and businesses strive for greener practices, opting for thermal printing papers that balance durability with low environmental impact becomes essential to align with both functional requirements and sustainability goals.

When selecting thermal printing paper, understanding the various sizes and compatibility with printers is crucial for achieving optimal performance. Thermal paper comes in a range of dimensions, from narrow rolls suitable for receipt printers to larger formats designed for label printing. Knowing the specific size your printer requires ensures seamless operation and minimizes paper wastage, making it essential to consult the printer specifications or user manual before making a purchase.

Compatibility goes beyond just size; it includes the paper type and thickness. Not all printers can handle every thermal paper variant due to differences in manufacturing standards and technology. For instance, some printers may require standard thermal paper, while others may be compatible with specialized options like synthetic or coated thermal paper, which might enhance durability and print quality. Recognizing these factors can help you select the right paper tailored to your application's needs, whether for high volume printing in retail or more specialized uses in logistics.

This chart displays the compatibility of various thermal paper sizes with popular printer types. It gives an overview of the most commonly used paper sizes and their corresponding printer compatibility percentages in 2025.