In the world of fabric printing, selecting the right Heat Transfer Printer Paper is crucial for achieving outstanding results. Industry expert Mark Johnson states, "Quality printer paper can transform your designs into captivating prints." His insight underscores the importance of understanding different paper types in the heat transfer process.

There are various options for Heat Transfer Printer Paper, each with unique qualities. Some are ideal for light fabrics, while others perform better on dark surfaces. It's essential to match the paper type to your project. Many beginners struggle with this selection and often choose incorrectly. This can lead to disappointing results.

Not all Heat Transfer Printer Papers are created equal. Some may fade quickly or peel off after washing. Experimenting with different brands could be beneficial, yet it may also become frustrating. Each trial presents an opportunity to refine your technique and improve your outcomes.

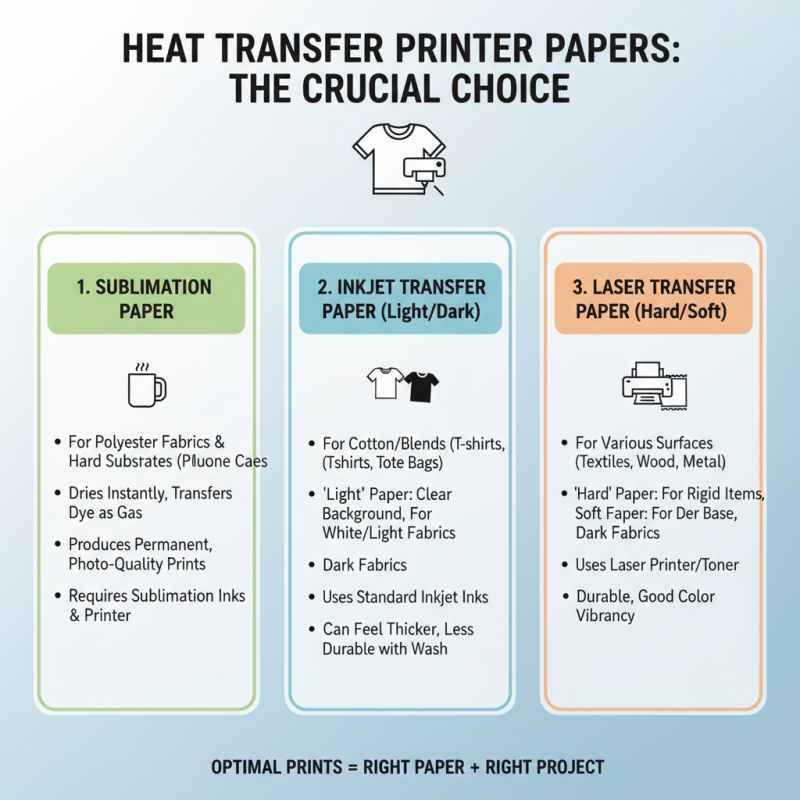

When it comes to heat transfer printing, the choice of paper is crucial. Different types of heat transfer printer papers yield varied results. Understanding these options helps achieve optimal prints.

One popular type is the inkjet heat transfer paper. It works well for vibrant colors. However, some users find it challenging with dark fabrics. Another option is the laser transfer paper, which is suitable for a variety of surfaces. It allows for detailed designs but can sometimes lead to issues with color fading.

Tip: Always test the transfer on a small piece of fabric first. This prevents larger mistakes during production. Choosing the right paper depends on your project's specifics. Some papers are better suited for cotton, while others work well with polyester or blends.

Don’t overlook the importance of weight and texture. Heavier papers often provide better durability. However, achieving a smooth finish may be difficult. Users sometimes report inconsistent results with glossy papers, leading to frustration. Choosing a matte finish might be a safer route for beginners. Adjusting your choice can enhance the final output.

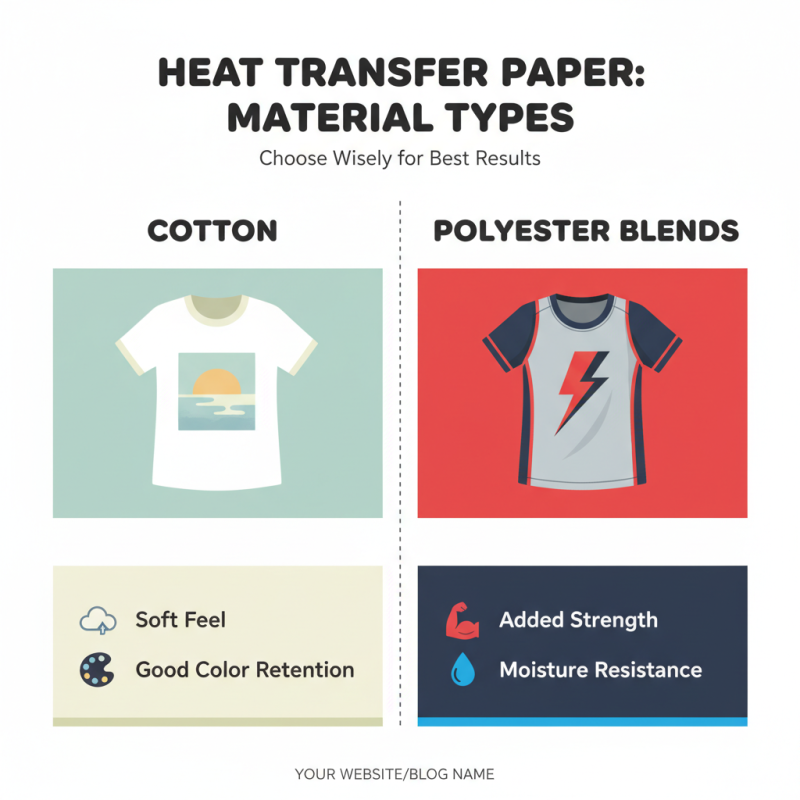

When selecting heat transfer printer paper, consider material type. The most common choices are cotton and polyester blends. This affects the final print quality and durability. Cotton offers a soft feel and good color retention. Polyester blends, however, provide added strength and moisture resistance.

Print resolution is another critical factor. Higher DPI settings yield sharper images. According to a recent industry report, papers with at least 300 DPI enhance the vibrancy of colors. You may also encounter specialty papers designed for specific fabrics. These can help achieve desired textures and finishes. However, finding the right match can be trial and error.

Tips: Ensure your printer settings align with the paper type. Inappropriate settings often lead to poor results. Test prints can save time and materials. Pay attention to paper weight too. Heavier papers typically transfer better but can affect printing speeds. Be ready for adjustments based on how the material interacts with your printer.

When choosing heat transfer printer paper, many brands claim to be the best. Each brand offers unique features. Some papers work well on cotton, while others shine on polyester. The right choice depends on your project needs.

Quality varies significantly. Some papers produce vibrant prints, while others may fade quickly. You might find that certain types peel or crack after a wash. Experimenting with different papers is essential to discover what fits your requirements.

Don’t overlook user reviews. They can reveal hidden issues. Printing tests are also crucial. Not every paper will yield the desired results on the first try. Keep an eye on the thickness and texture. These factors influence the final product.

When considering heat transfer printer paper, choice matters significantly. Different types of paper present unique attributes. Each paper type yields varying results in print quality, durability, and transfer ease. For instance, the synthetic paper often provides high durability, while cotton and bright white papers deliver vibrant colors and detailed images.

According to industry reports, around 70% of professionals favor light-colored heat transfer papers. These papers typically transfer inks more effectively. However, using dark or colored papers can lead to a mismatch in tones. A study highlighted that paper thickness impacts print quality. Thicker papers may resist cracking but can potentially lead to a less smooth transfer.

Reflecting on user experiences, many report mixed results. Some users find that matte finishes result in muted colors, which may not be ideal for every design. On the flip side, glossy papers can offer sharp images but often exhibit more fade over time. The question arises: Is it worth sacrificing durability for visual appeal? Balancing these factors requires thoughtful consideration and experimentation. Ultimately, the choice of heat transfer paper should align with specific projects and desired outcomes.

| Paper Type | Material Compatibility | Transfer Method | Best For | Color Vibrancy | Durability |

|---|---|---|---|---|---|

| Inkjet Transfer Paper | Cotton | Heat Press | T-Shirts | High | Moderate |

| Laser Transfer Paper | Polyester | Heat Press | Mugs & Apparel | Very High | High |

| Dark Fabric Transfer Paper | Dark Fabrics | Heat Press | Black/Colored Shirts | Moderate | Moderate |

| Sublimation Paper | Polyester | Heat Press | Beverage Containers | Exceptional | Very High |

| Light Fabric Transfer Paper | Light Fabrics | Heat Press | Light Garments | High | Moderate |

| Vinyl Transfer Paper | Various Materials | Heat Press | Apparel & Signs | High | Very High |

| Photo Transfer Paper | Various Surfaces | Heat Press | Photos & Artworks | High | Moderate |

| Non-Woven Transfer Paper | Textiles | Heat Press | Costumes | Moderate | High |

| Aqueous Transfer Paper | Natural Fibers | Heat Press | Shirts & More | High | Moderate |

| Glitter Transfer Paper | Cotton & Polyester | Heat Press | Decorative Apparel | Very High | Moderate |

When using heat transfer papers, the right technique can make a significant difference. To achieve the best results, it's essential to consider factors such as temperature, pressure, and time. According to industry reports, improper settings can lead to faded images or poor adhesion. For example, printing at the wrong temperature can compromise quality. Aim for a consistent temperature around 375°F for most materials.

Tips for achieving exceptional results include preparing your fabric correctly. Wash and dry the fabric to remove any residues. Pre-press it for a few seconds to eliminate moisture. This step can help enhance the transfer’s longevity. Using a heat press can also provide even pressure, which is crucial. Make sure to apply the correct amount of pressure during pressing; too little can cause peeling.

Another valuable tip involves choosing the right type of transfer paper for your project. Different materials require specific paper types. For example, cotton fabrics may perform better with certain papers over others. I’ve heard feedback from users who regretted not doing enough research prior to their printing. Mistakes in paper selection can ruin an otherwise perfect design.

This chart illustrates the effectiveness of various types of heat transfer printer papers based on a review of key factors such as color vibrancy, durability, ease of use, and cost-effectiveness. Each type is rated on a scale of 1 to 10, with 10 being the best performance possible.